Root cause analysis: Difference between revisions

Amwelladmin (talk | contribs) No edit summary |

Amwelladmin (talk | contribs) No edit summary |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{ | {{a|devil| | ||

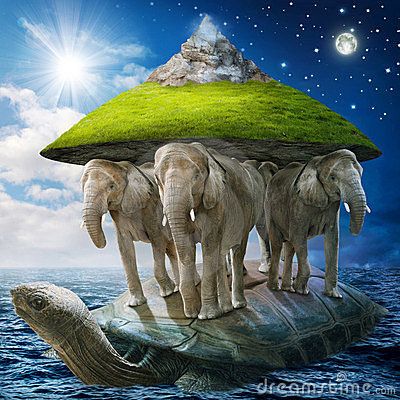

[[File:Elephants and turtle.jpg|450px|thumb|center|A [[root cause]], yesterday]] | |||

}}A management technique designed to systematically identify the cause of problems on an established manufacturing process. From the little I know about it, involves behaving like a five-year-old and asking the same question — “why?” over and over again. | |||

This makes some sense in a production-line context, where there are defined inputs and outputs, and one has already reduced the world to a [[nomological machine]]. | This makes some sense in a production-line context, where there are defined inputs and outputs, and one has already reduced the world to a [[nomological machine]]. These are [[Simple system|simple]] and [[complicated system]]s. | ||

It works less well when you are a pioneer, fighting through jungle thickets, seeking the Indies via a western route, or rolling in your wagon train into the salted deserts of what is now, but wasn’t then, Utah. These are complex systems. Accident investigation theory from {{author|Sidney Dekker}} has the following observation: | |||

:''We think there is something like ''the'' cause of a mishap (sometimes we call it the [[root cause]] or the [[primary cause]]), and if we look in the rubble hard enough, we will find it there. The reality is that there is no such thing as ''the'' cause, or [[primary cause]] or [[root cause]]. Cause is something we construct, not find.''<ref>{{fieldguide}}, 33.</ref> | |||

===Example=== | |||

Wikipedia gives the following, somewhat implausible example where the problem is that your car won’t start. | |||

*Why won’t my car start? – Because the battery is dead. | |||

*Why is the battery dead? – Because the alternator doesn’t work. | |||

*Why won’t the alternator work? — Because the alternator belt has broken. | |||

*Why has the alternator belt broken? – Because the alternator belt was worn out and not replaced. | |||

*Why was the alternator belt not replaced in time? – Because you didn’t maintain the car according to its recommended service schedule. | |||

Thus: the root cause of your problem is that ''you didn’t follow regulations, you naughty little squirrel''. [[Operator error]]; a failure to attend to a [[second-order derivative]] [[process]]. Now if that seems a little implausible to you, you have at least ''me'' for company. And, I think, {{author|Sidney Dekker}}. And {{author|Charles Perrow}}, were he still around. Notice the industry here: to reduce a problem to a ''fundamental breach of a [[process]]'': a [[heuristic]] or algorithm designed to defend against the intractable messiness of the universe, but which treats that universe like a super-complicated game of [[Go]]. | |||

Notice the industry here: to reduce | |||

{{sa}} | {{sa}} | ||

*{{fieldguide}} | |||

*[[Toyota Production System]] and the [[seven wastes]] | *[[Toyota Production System]] and the [[seven wastes]] | ||

{{ref}} | |||

Latest revision as of 10:39, 25 November 2020

|

A management technique designed to systematically identify the cause of problems on an established manufacturing process. From the little I know about it, involves behaving like a five-year-old and asking the same question — “why?” over and over again.

This makes some sense in a production-line context, where there are defined inputs and outputs, and one has already reduced the world to a nomological machine. These are simple and complicated systems.

It works less well when you are a pioneer, fighting through jungle thickets, seeking the Indies via a western route, or rolling in your wagon train into the salted deserts of what is now, but wasn’t then, Utah. These are complex systems. Accident investigation theory from Sidney Dekker has the following observation:

- We think there is something like the cause of a mishap (sometimes we call it the root cause or the primary cause), and if we look in the rubble hard enough, we will find it there. The reality is that there is no such thing as the cause, or primary cause or root cause. Cause is something we construct, not find.[1]

Example

Wikipedia gives the following, somewhat implausible example where the problem is that your car won’t start.

- Why won’t my car start? – Because the battery is dead.

- Why is the battery dead? – Because the alternator doesn’t work.

- Why won’t the alternator work? — Because the alternator belt has broken.

- Why has the alternator belt broken? – Because the alternator belt was worn out and not replaced.

- Why was the alternator belt not replaced in time? – Because you didn’t maintain the car according to its recommended service schedule.

Thus: the root cause of your problem is that you didn’t follow regulations, you naughty little squirrel. Operator error; a failure to attend to a second-order derivative process. Now if that seems a little implausible to you, you have at least me for company. And, I think, Sidney Dekker. And Charles Perrow, were he still around. Notice the industry here: to reduce a problem to a fundamental breach of a process: a heuristic or algorithm designed to defend against the intractable messiness of the universe, but which treats that universe like a super-complicated game of Go.

See also

- Sidney Dekker’s The Field Guide to Human Error Investigations

- Toyota Production System and the seven wastes